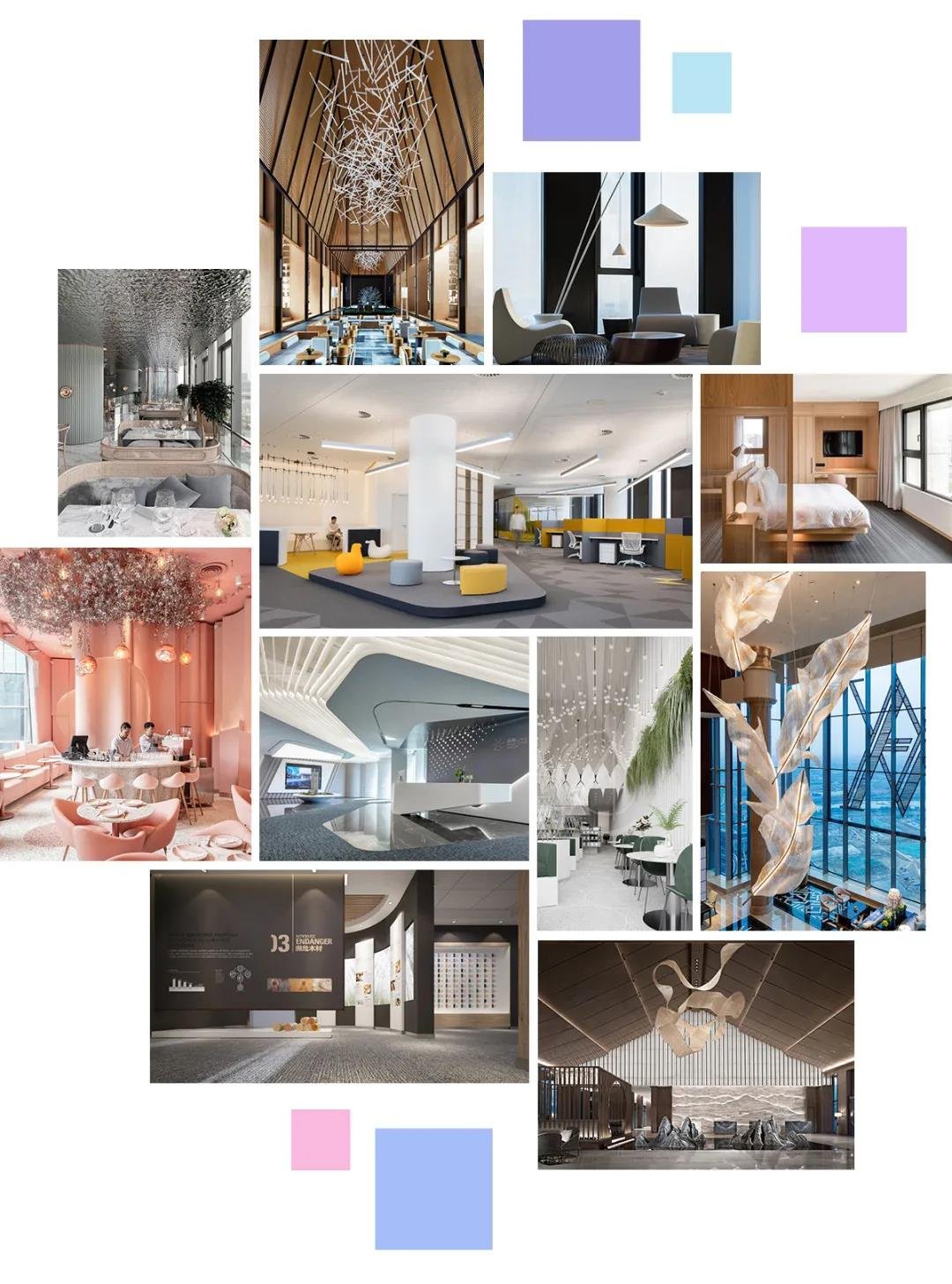

Much excellent design works in the past two years

There is an arc shape

The curved lines are beautifully drawn

But the construction landing is the difficulty of the project

When the “board” of the fabricated wall panel meets the “arc” shape

What should I do?

This article is about inorganic, wood, metal

Composite, wood-plastic and stone-plastic

The five major types of materials have been sorted out by application methods

Inorganic sheet

Magnesium sulfide board

Arc sun angle: factory prefabricated arc sun angle

Curved wall: thin plate can be bent on site

Slate:

Arc angle: 6mm factory prefabricated and bendable 125°

Curved wall: 3mm curved wall, 15° bendable at the construction site

Calcium silicate board:

Arc sun angle: factory-made, grooved resin filling

Curved wall: Not currently supported

Enhanced gypsum board:

Arc sun angle: adopt aluminum or other product sun angle lines

Curved wall: cannot be curved

Metal sheet

Aluminum honeycomb panel:

Arc sun angle: same color aluminum profile sun angle line or factory prefabricated

Curved wall: factory prefabricated

Aluminum veneer:

Arc sun angle: finished sun angle made of other materials

Curved wall: keel rolling arc type, factory prefabricated

Wood-plastic and stone plastic

Bamboo wood hollow board:

Arc sun angle: same color aluminum profile sun angle line or factory prefabricated

Curved wall: slotted at the back, curved in construction

Bamboo wood solid board:

Arc sun angle: finished sun angle line

Curved wall: 9mm plate is curved and slotted at the back

5mm sheet direct construction and bending

SPC board:

Arc sun angle: finished sun angle line/individual products can be bent

Curved wall: large radius can be achieved

Foamed PVC board:

Arc sun angle: finished sun angle line

Curved wall: 9mm plate is curved and slotted at the back

5mm sheet direct construction and bending

Compound class

Anti-fold special board:

Arc sun angle: prefabricated sun angle bar

Curved wall: thick plate prefabrication / thin plate construction bending

Can be L-shaped, U-shaped, M-shaped, V-shaped

A2 fireproof board:

Arc sun angle: slotting and bending

Curved wall: the flat installation process can be bent in construction, and the radius is not less than 30mm

If the steel frame is composite, it will be prefabricated in the factory and treated with arc rolling

Aluminum plastic panel:

Arc sun angle: can be slotted and bent, or factory prefabricated radian

Curved wall: flexible construction

Ceramic aluminum composite board:

Arc sun angle: can be grooved and bent or prefabricated in the factory

Curved wall: does not support construction bending

Wooden board

Density board, Ou Song board or multilayer board,

Arc sun angle: other material finished sun angle line or factory prefabricated

Curved wall: it can be constructed by bending the thin plate or prefabricated in the factory

Arc line metal strip

In the prefabricated interior decoration system, aluminum is the most widely used.

In principle, due to the mass production of aluminum profiles, the production process is mainly based on extrusion process + colored oxidation/spraying/electrophoresis, and the extrusion process is destined to be straight.

If you need to customize the bending, you need to adjust the process, extrusion process + bending + Lass sandblasting + colored oxidation/spraying / electrophoresis, the manufacturer needs OEM service and bending equipment

Stainless steel can be made into a curve, but the complex shape of stainless steel cannot be realized

Summarize

Facing the arc shape, we need to consider the following aspects:

- Fire rating requirements

- Combination schemes and production feasibility of curved walls, straight walls, arc external angle materials and base materials

- How to connect the curved plate, straight plate and external angle

- How to realize the synchronous curve of decorative lines

- Between factory prefabrication and on-site construction bending, it is necessary to evaluate and trend from several aspects such as feasibility, installation effect and cost (production, transportation, vertical transportation, secondary cost after errors), etc.