Mention terrazzo is a household name

I probably still stay in the 80s in my memory

Although it is wear-resistant, it has an indescribable sense of cheapness

With the progress of the times, it is gradually replaced by new materials

And in recent years

Terrazzo is gradually returning to the public eye

The terrazzo that was once rejected has actually begun to counterattack

Is it still the terrazzo in our eyes?

01.

What is terrazzo

△Traditional terrazzo is a building material made by mixing glass, quartz stone, and other raw materials into cement. In terms of materials and craftsmanship, it is divided into pouring terrazzo ground and plate terrazzo ground. Because of its high wear resistance, no dust accumulation, diverse material color matching, and strong decoration, it is widely used in construction.

“Features of Terrazzo”

Artificial stone has the natural texture and firm texture of marble, as well as the smoothness and fineness of ceramics, as well as easy processing and rich patterns. As a renewable material, it can display endless creativity in a limited space.

The material characteristics of terrazzo have outstanding performance in all aspects, such as non-toxic, non-radioactive, flame retardant, non-stick oil, non-bleeding, antibacterial and mildew proof, abrasion resistance, impact resistance, easy maintenance, seamless splicing, variety of shapes, and so on.

The specific features are as follows:

(1) Rich colors and rich patterns. Pure colors, such as white, yellow, black, red, etc. There are also colors such as hemp color that highlight the texture, that is, particles of different colors and different sizes are added on the basis of the clean color board.

(2) The materials of the terrazzo have been screened to contain no radioactive substances and no radioactive contamination. Very safe to use.

(3) Terrazzo has moderate hardness and toughness and has better impact resistance than natural stone.

(4) Convenient processing and production: Terrazzo can be processed like hardwood, and all woodworking tools and mechanical equipment can be used for the production and processing of artificial stone. Special glue can be used, and all kinds of tabletops can be polished after bonding and can be “seamless.” . It can also be processed into various shapes, which are unmatched by natural stone, which is also a big move to beat other materials.

(5) Compact structure, clean and hygienic. Artificial stone has a dense structure, no micropores, liquid substances cannot penetrate, and bacteria cannot grow in it. Therefore, it is reasonable for some businesses to call artificial stone “antibacterial stone”.

“Terrazzo Classification”

According to the construction and production process, the terrazzo is divided into on-site terrazzo and prefabricated terrazzo ground

“In-situ terrazzo”

Pure terrazzo must be poured on-site, commonly known as cast-in-place terrazzo. Simply put, it means mixing natural crushed stone, glass, or even some precious gems, jade seed materials and other aggregates and pigments into the cement, and then polished and polished after setting. The formed cement products require on-site construction and can be arbitrarily parqueted. They can be dyed into various colors with pigments, and glass or copper strips are used as partitions, which have a good decorative effect.

“Prefabricated Terrazzo”

Prefabricated terrazzo is uniformly produced on the production line of the factory by a production machine, and the prefabricated terrazzo slabs are directly pavement when needed. The gloss is higher than the terrazzo constructed on-site, but the decoration is not as good as the terrazzo constructed on-site. Due to the need to use cement joints when paving on-site, the joints will turn black after a long time, easy to hide dirt and dirt, and often smell the terrazzo odor.

According to the effect of use, it can be divided into industrial terrazzo, civil water terrazzo, commercial terrazzo, etc.

“Industrial Terrazzo”

The industrial terrazzo floor is the original color terrazzo floor. It is generally used in workshops, warehouses or parking lots of factories. Its raw materials are granite grains and ordinary Portland cement. The surface is not beautiful but the cost is cheap and durable.

“Civil Water Millstone”

Civil terrazzo flooring is used on the ground of villas, hospitals, squares, subway stations, etc. It is more ornamental and grade than industrial terrazzo. Green and red marble particles, high-grade white cement, or colored cement are generally used, and the cost is similar to ordinary The polished tiles are of the same grade.

“Commercial Terrazzo”

Commercial terrazzo flooring is used on the floors of shopping malls, shopping malls, office buildings and other commercial areas. It requires beautiful and high-grade, dust-free and wear-resistant, easy to clean, and has the same effect as marble, but the cost is no more than one-third of marble.

02.

Terrazzo construction technology and maintenance

“Terrazzo construction technology-cast-in-place or paving bricks”

The big names can fly, can we use them at home? If you want to use terrazzo at home, you have the following options:

“Pouring on-site”

There are currently two processes for on-site pouring: one is traditional cement terrazzo, which is simple in construction and cost-effective, but it is easy to wear and has limited appearance; the other is epoxy terrazzo, which is beautiful and wear-resistant, but the price is more expensive and the material is environmentally friendly. Not as good as cement.

Traditional production process:

Basic treatment → finds elevation → elastic horizontal line → spread screed mortar → maintenance → elastic grid line → inlay grid strip → mix terrazzo mixture → paint cement slurry bonding layer → spread terrazzo mixture → roll wiping Flat → trial grinding → rough grinding → fine grinding → polishing → oxalic acid cleaning → waxing and polishing.

In the early stage of on-site pouring, you need to buy raw materials and find a construction team, and the various mixers and grinders that need to be used at that time are not easy to transport. If the construction area is not large, some people may not be willing to contract. Many companies will only do it with more than 100 square meters. And just after pouring, the floor should be raised for one month first. If the decoration cycle is arranged tightly, the subsequent decoration process may be delayed.

“Prefabricated Terrazzo”

“Terrazzo Brick”

Due to certain restrictions on pouring terrazzo on-site, terrazzo bricks are a good substitute. There are two choices for terrazzo bricks: terrazzo bricks and imitation terrazzo bricks. The terrazzo bricks are pre-poured and cut terrazzo. The construction is simple and the texture is good.

The imitation terrazzo brick is a ceramic tile that imitates the terrazzo texture. It is the most cost-effective way. Although the texture is not as good as the terrazzo brick, many bricks can be made fake and real.

(1) Prefabricated terrazzo on the wall process

We can understand the prefabricated terrazzo slabs as natural stone or ceramic tiles. Because from the point of view of the craftsmanship of the wall, the difference is not that big. Mainly use dry hanging and wet sticking. Only after completion, an overall polishing process will be done. Therefore, the way of terrazzo on the wall can be realized by referring to the dry hanging off the stone.

The thickness specifications of the terrazzo prefabricated plates are divided into 15mm, 20mm, and 30mm. We only need to reserve a minimum thickness of 80mm for the finished surface, and the other expressions are exactly the same as the joints of the stone dry hanging.

(2) Prefabricated terrazzo wet pasting process

As mentioned earlier, prefabricated terrazzo can be understood as natural stone and can be hung dry at the same time. Therefore, prefabricated terrazzo can also be installed on the wall by wet pasting.

However, compared with natural stone, there is fewer terrazzo on the wall, so less stone is used for wet pasting on the wall.

Therefore, for the method of wet pasting the terrazzo on the wall, you can also refer to the standard wet pasting process on the wall.

How to maintain the terrazzo

The first requirement of decoration is to be well taken care of!

Some people may worry that although the terrazzo is good-looking, it is too much trouble to take care of. The editor once did an experiment in which soy sauce was sprinkled on the terrazzo. After 6 hours, it would be wiped off. The daily dust and stains in the house It’s still relatively easy to take care of.

In addition, the mineral composition in the terrazzo floor is more complex, especially the iron composition in the light-colored terrazzo floor, which often produces rust in humid conditions.

You can buy a professional terrazzo cleaner to clean the floor. If you don’t have it at home, use ordinary washing powder water or liquid detergent. If it is difficult, you can use the commonly used toilet cleaner, toilet cleaner, and the like to clean the bathroom, but may There will be some wear and tear.

The best way to do it once and for all is to make a layer of sealing curing agent on the surface of the terrazzo, which can not only have the brightness of the tiles but also prevent dust and harden it~

03.

Excellent cases of terrazzo at home and abroad

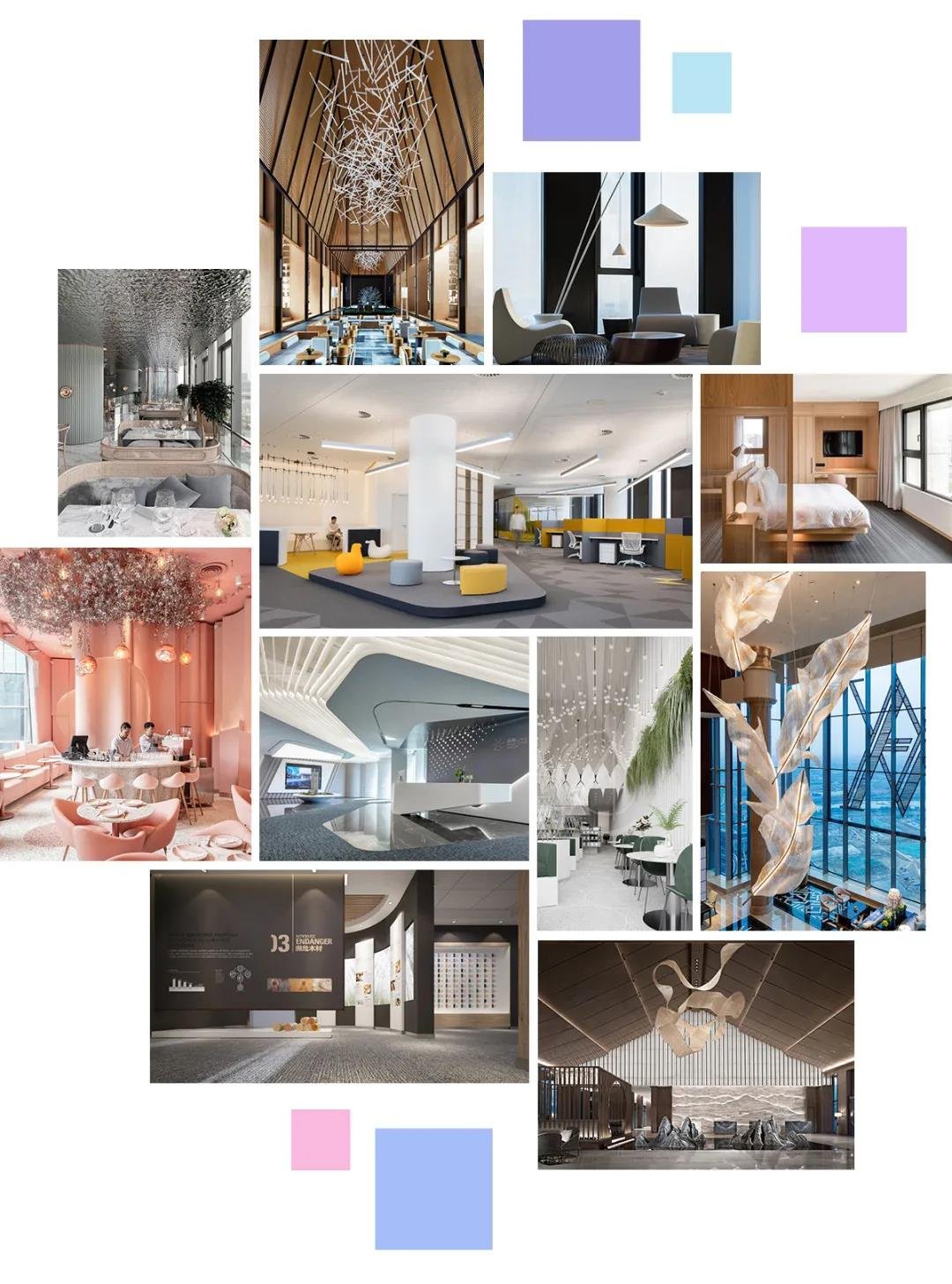

With the enrichment of materials and the advancement of manufacturing technology, terrazzo presents richer colors and patterns. Under the creative application and collocation of designers, whether it is terrazzo’s delicate material or its texture and shape, it becomes The darling of the decoration industry has stepped onto the international stage and has its beautiful appearance in industries such as commercial space, homes, furniture, ornaments, and lamps.

The most attractive thing about terrazzo is the diversity of its colors and collocations. If you pay attention, you will find that terrazzo is used in many public places.

“Foreign excellent case application”

The Dutch company Actual has developed a new technology for 3D printing flooring, which can add endless colors and patterns to the terrazzo floor. The shape and size can be customized and full of creativity~

The famous British designer David Chipperfield has used terrazzo to the extreme. He designed a number of flagship stores in New York, Rome, Paris, London, and Shanghai for the luxury brand Valentino with terrazzo, so that some people call it “the most beautiful terrazzo model room.” The pure and elegant terrazzo space has a high-end and fashionable atmosphere, and the effect is really extraordinary.

Jingshui Huayue is located in Nanjing, China. It is a modern and fashionable essential oil massage place. It breaks the traditional impression of darkness and mystery. It uses the delicate and unique material of light-toned terrazzo on a large scale to create a clean, comfortable and pure space.

In recent years, these high-value terrazzos can not only add pigments to the cement but also add a variety of beautiful natural gravel, glass, and even gems, jade seeds, etc., to form a colorful tone.