The first time you see the rock slabs

I guess it will feel quite fresh

This material feels like marble and like stone

The knocking sounded like rock and like ceramic

What the hell is it?

The slab is described in English as ENTERED STONE

It means “sintered stone”

It is a new type of material that belongs to the category of plates

It can be understood as being from ceramic large plates and ceramic sheets

Upgraded versions and new categories derived from it

Because of its excellent physical properties

and powerful cross-border application capabilities

Become a supernova of environmentally friendly materials

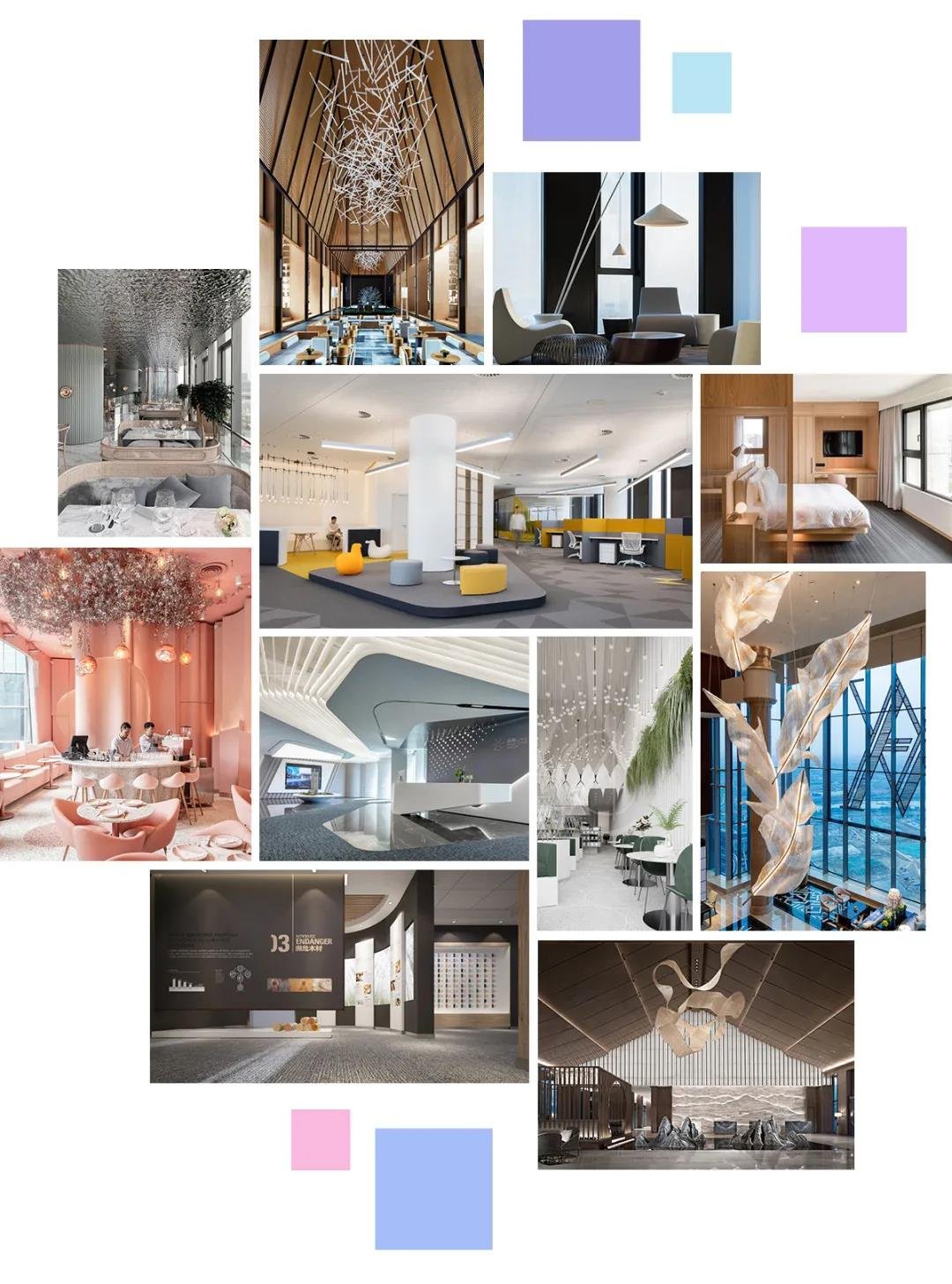

Highly respected and loved by designers

01.

High “rock” value, hard power

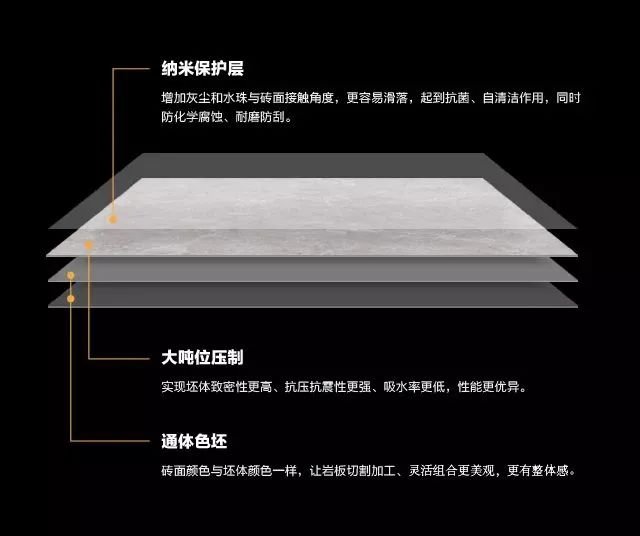

The rock slab is composed of natural minerals, pressed by more than 10,000 tons of presses, and then fired at a high temperature above 1200 °C, it is a large new porcelain material that can withstand the processing process of cutting, drilling, grinding, and so on.

“Material Properties of Rock Slabs”

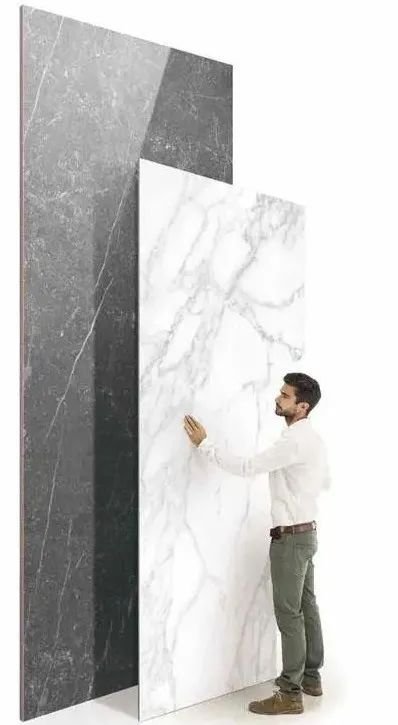

1, bigger, lighter, thinner.

Can be made into very large specifications with a very thin thickness of 3600 *1200 * 3mm, reducing the gap of space material splicing; the average weight of traditional tiles is 23~27kgs/㎡, while the average weight of ultra-thin rock slabs is only 7kgs/㎡;

2. High hardness, impact resistance, strong wear resistance.

High temperature and high pressure generated rock slab, Mohs hardness of more than 6 levels, scratch resistance, wear resistance can be directly tested with steel knives scratches, known as “building materials industry Wolverine”; the rock slab extremely strong corrosion resistance can also be used for acid and alkali laboratory countertops, hospital antibacterial walls and operating tables and other places with high requirements.

Mohs hardness uses the scratch method to scratch the surface of the mineral under test and scratches, and the Mohs hardness is customarily used in mineralogy or gemology. The depth of the measured scratch is divided into 1 to 10 steps to indicate the hardness, which is extended from left to right.

▽

3. High-temperature resistance, anti-permeation, acid, and alkali corrosion resistance.

The fire coefficient of the rock slab reaches A1 level of non-combustible, the safety factor is high, the water absorption rate is as low as 0.06%, the product is not deformed, does not fade, and is almost unaffected by changes in external temperature.

4. Anti-fouling, more anti-slip

It is fired at high temperature, the surface is all-porcelain, combined with nano-scale anti-fouling treatment, and improves the anti-slip performance of traditional tiles.

5. Energy saving and low carbon, safe and zero radiation.

Compared with traditional tiles, it saves more than 60% of raw material resources, reduces comprehensive energy consumption by more than 50%, reduces exhaust gas emissions by more than 80%, is non-toxic and non-radiation- and can be in direct contact with food.

6. Easy to cut and easy to pave

It is easy to cut into different specifications and recombine into different paving forms, which can save more labor costs and time costs, and there is a variety of paving construction methods to effectively shorten the construction cycle.

7. Strong decoration and high space utilization

The specifications are larger, the décor is rich, and the texture and texture are more simulated to various natural materials, which is thinner than the tile slab, which maximizes the utilization rate of space resources.

“Rock Slab ≠ Ceramic Slab”

If the rock slab is a new type of ceramic plate, then the ceramic plate is closer to the enlarged version of the traditional tile, they are two completely different products, the mineral composition and crystal structure of the two are completely different, the product characteristics are not the same.

The most essential difference between rock slabs and large plates is that the rock slabs have the conditions for deep processing due to the special ratio of raw materials and the special process. Compared with the ceramic plate, the rock slab is more flexible and elastic, and can withstand secondary processing such as machining and cutting, opening hole drilling, chamfering, slotting, waterjet, etc. It is not easy to crack, and the same cutting method is used for ceramic large plates, which also makes the rock slab more possible for home applications.

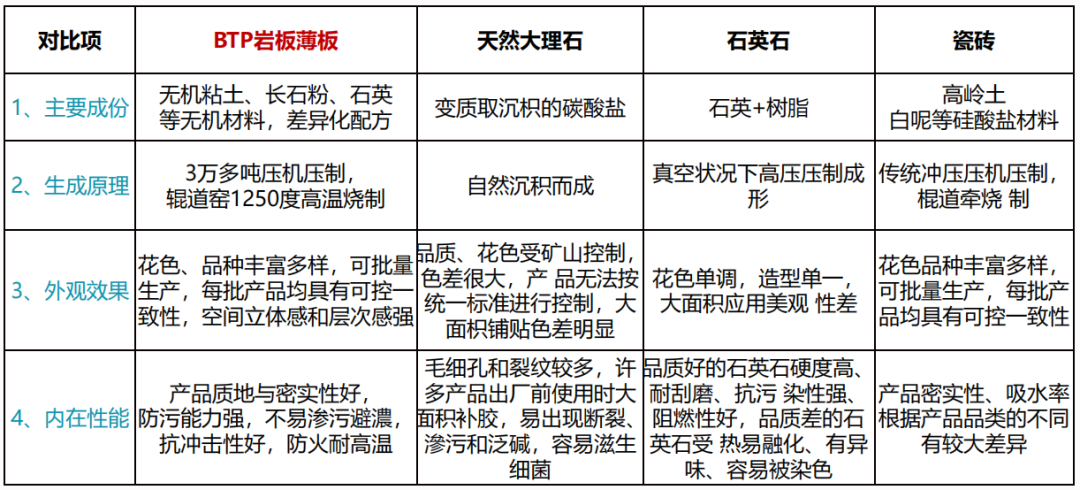

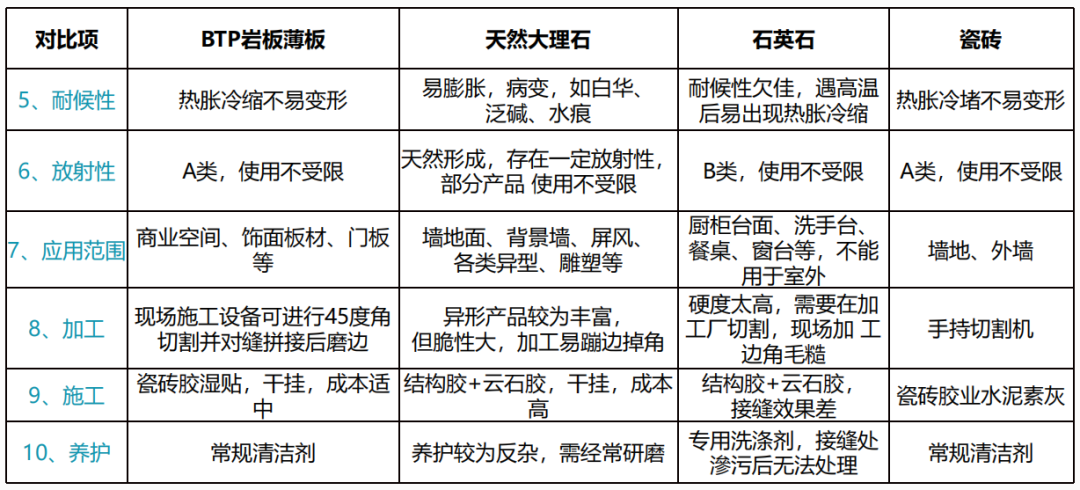

Comparison of rock slabs and natural marble, quartz stone, tiles

▽

Image source BTP Slabs

“Slab Defects”

The slab has many performance advantages and many defects, and we need to understand it

1. The slab is prone to a burr in the case of insufficient compression, which requires the process.

2. Because the rock slab has toughness, its deep processing products are too brittle, fragile, and easy to produce cutting and cracking, and there are safety hazards.

3. The cutting difficulty is large, the hardness of the rock slab material is large, the fine cutting is difficult, and there are certain requirements for construction technology.

4. In the process of transportation and installation, the edge of the rock slab will have a brittle burst edge on the spot, so the transportation requirements are high.

“Rock Slab Specifications”

The slab size is wide, and the conventional sizes are:

3600×1200mm ×(3mm,6mm), suitable for wall, finish, kitchen cabinet door panel;

3200×1500mm ×(6mm, only a few decors have 3mm), suitable for wall, finish, kitchen cabinet door panel;

3200×1600mm ×(12mm,20mm), suitable for kitchen countertop, tabletop, floor.

“Rock Slab Price”

At present, there are three main ranges in the price of the slab market:

1. Low-end rock slab price:100~400 yuan /㎡

2. Price of mid-end rock slabs:500~1000 yuan /㎡

3. High-end rock slab price:1500~3000/㎡

(The advantages and disadvantages and prices of the products of each brand are different, for reference only)

02.

Cut casually

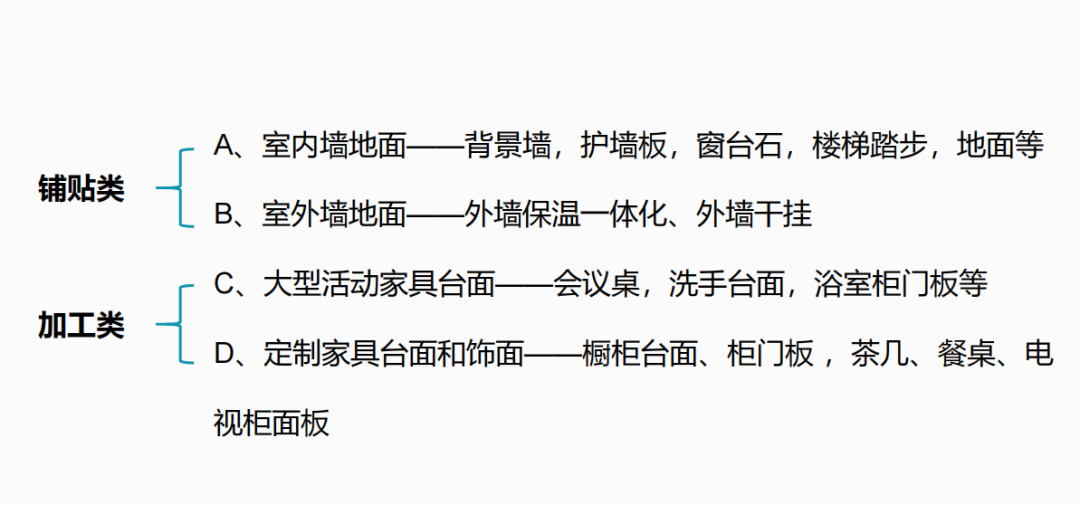

Wide range of applications

Slabs are a MATERIAL THAT CAN BE DIY

It depends on the designer’s brain hole and people’s needs

In the eyes of designers

A thin slab of rock is like a piece of cloth that has not yet been cut

The larger the size, the more space there is for the cropped design

From the current point of view

In addition to rock, slabs can not replace stone special-shaped products

Where ceramics and stone plates can be decorated

The slabs can be replaced

Based on the above advantages

Rock slabs are widely used by many home enthusiasts

Building facades, interior floors, walls,

Bathroom space, countertops, furniture panels, and other fields

▽

Image source BTP Slabs

“Building Facades”

Based on the physical properties of fireproof, frost-resistant, and high-temperature resistance, rock slabs are a very friendly choice for building facade materials, and the fire rating is A1.

“Indoor Walls, Floors”

The large-scale rock slab + stone texture effect can better show the gorgeous and high-grade sense of the indoor space.

The slabs are generated at high temperatures and high pressures, with a hardness of more than 6 levels, and direct use of steel knives will not cause scratches or damage to the slabs, and they are also extremely wear-resistant when used as the ground.

“Door Wall Space”

The application of rock slabs to the door wall system, in addition to giving consumers a heavy and down-to-earth feeling, also organically combines the door and the wall, which is natural.

「Staircase Application」

The hardness and flexural strength of the rock slabs are far more than ordinary tiles, even if the force is uneven, even if it is trampled daily, it can be competent, and the whole process can be as practical and beautiful as stone in the stair corners and anti-slip groove functions.

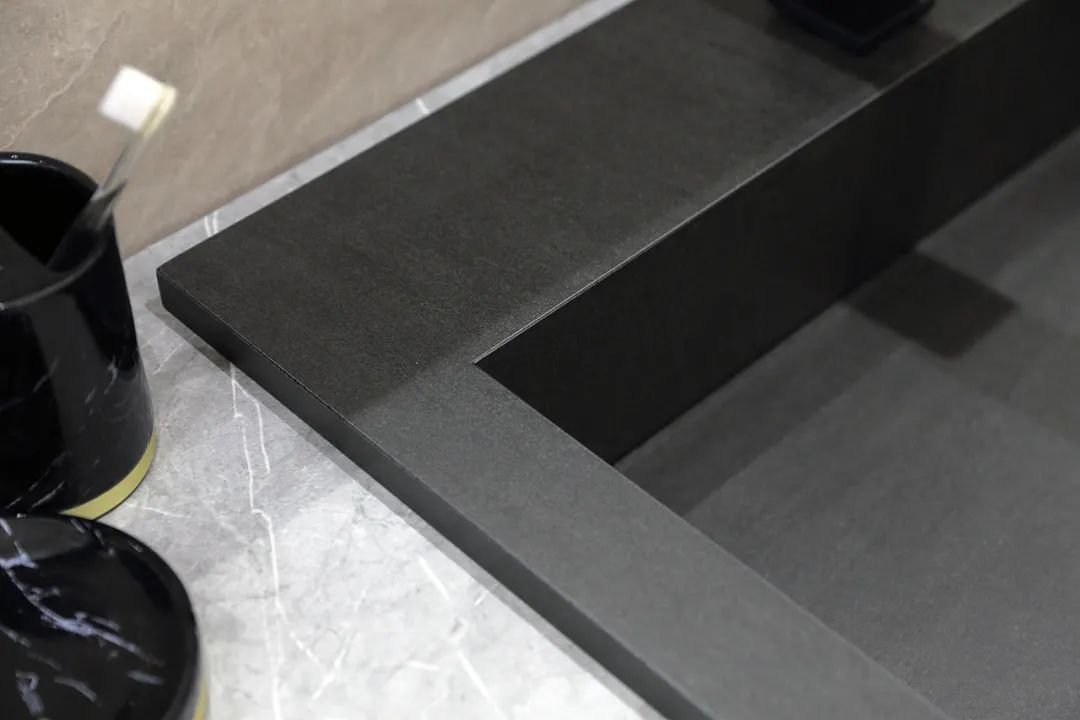

“Countertop”

The rock slab itself is sintered at a high temperature of 1250 °C, does not change color in case of high temperature, does not smoke, does not release harmful substances, fire retardant does not fade, Mohs hardness is as high as 6 grades, no fear of knife tip scratching can be directly in contact with food, very suitable for use in kitchen countertops and cabinet door panels.

「Bathroom Space」

The unique nano-protective layer of the rock slab makes the board mask have excellent properties such as zero water absorption and zero penetration, antibacterial and bacteriostatic, anti-chemical corrosion, etc., and are also excellent in the bathroom space.

“Use on Furniture”

The rock slab can be drilled, polished, cut and other deep processing, suitable for a variety of shapes, the thickness of the countertop is only 1/3of the traditional tile, can also be used in furniture manufacturing.

03.

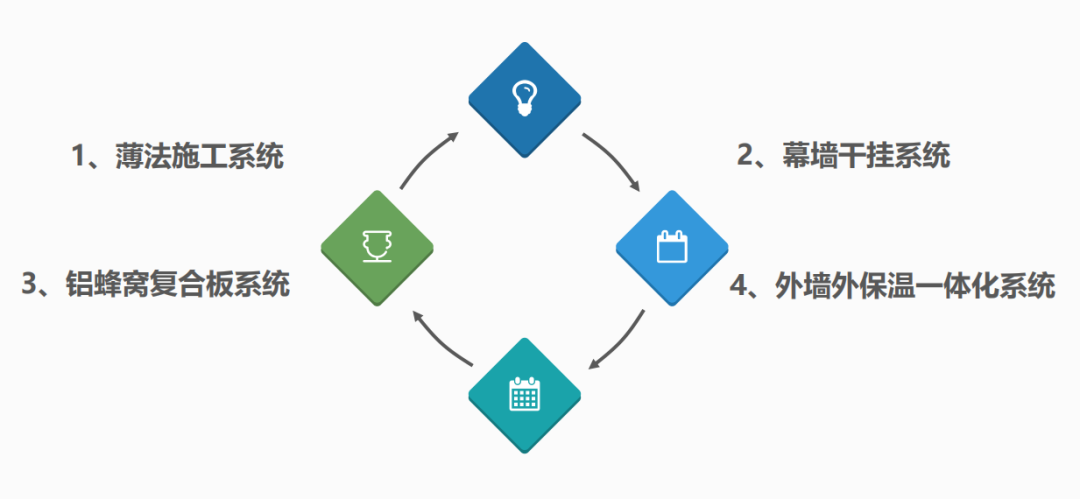

Rock slab construction process

There are two main types of rock slab construction processes: gluing and dry hanging.

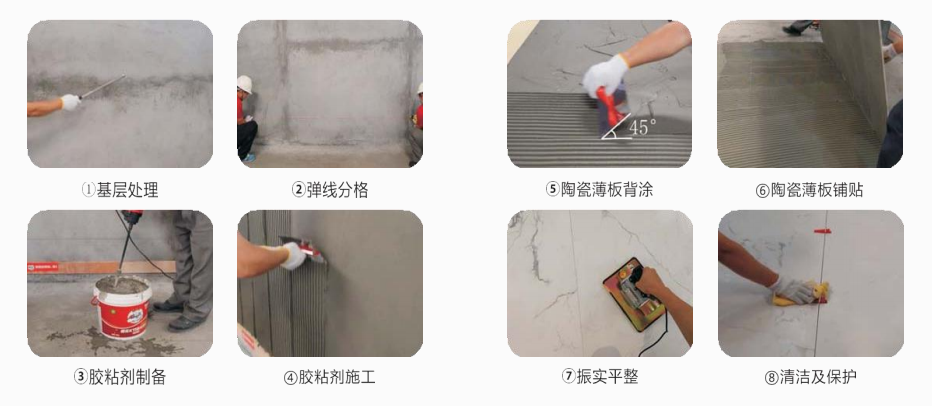

1. Rock slab laying process

Base treatment → Elastic line segmentation → Adhesive preparation → Adhesive construction → Rock slab back coating Large rock slab paving → vibration solid flattening → Surface cleaning and protection → caulking treatment.

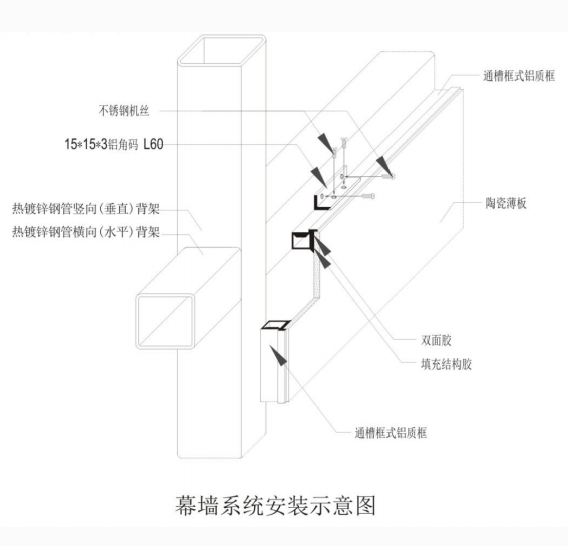

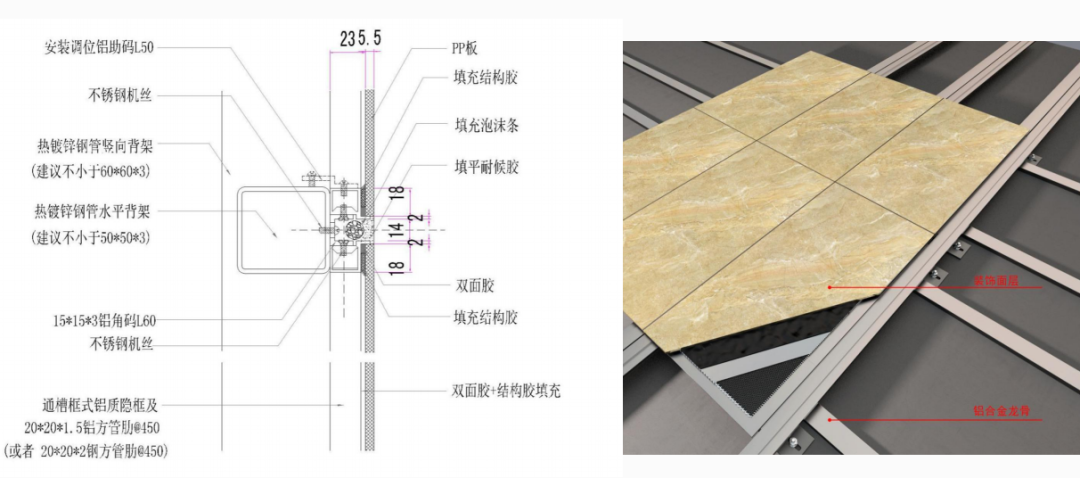

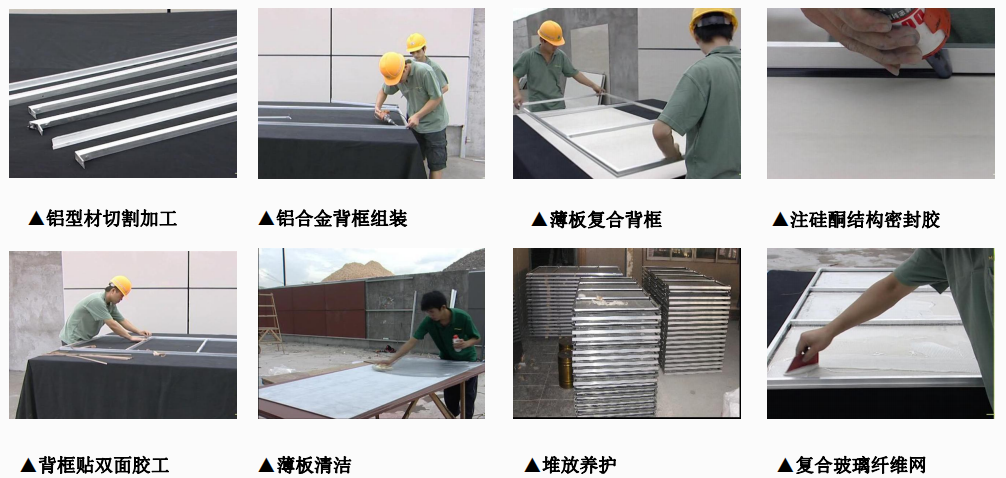

2. Curtain wall dry hanging system

Aluminum profile cutting processing → Aluminum alloy back frame assembly → back frame paste double-sided adhesive → sheet cleaning → sheet composite back frame → injection silicone structure sealant → Composite glass fiber mesh → stacking and maintenance

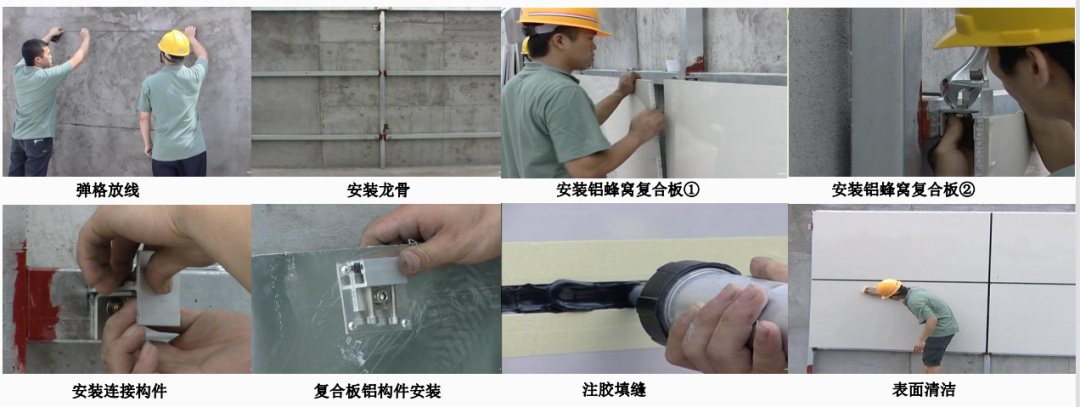

3. Aluminum honeycomb composite board process

Elastic grid release → Mounting keel → Mounting connecting member → Composite panel Aluminum member Mounting → Mounting aluminum honeycomb composite panel → Gluing caulking → Cleaning surface.

4. External wall insulation integration system

Base Wall Treatment → Lattice Release Line, Drilling → Polymer Bonding Mortar Formulation → Back Plate Adhesive → Bonded Sheet Energy Decorative Board → Mounting System Butterfly Anchor Pendant → sealant or grout grapple → clean surface → acceptance