Introduction to the material

Wood-plastic, also known as plastic wood, or Wood-Plastic Composites (WPC), refers to the use of polyethylene, polypropylene, and PVC, etc., instead of the usual resin adhesive, with more than 35%-70% of wood powder, rice shell, straw, and other waste plant fibers mixed into new wood materials, and then by extrusion, molding, injection molding, and other plastic processing processes, the production of sheet or profile. Mainly used in building materials, furniture, logistics packaging, and other industries. The plate formed by heat extrusion after mixing plastic and wood powder in proportion is called extruded plastic composite sheet.

Material properties and characteristics

Wood-plastic composites contain plastic, so they have a good elastic modulus. In addition, because of the fiber contained and fully mixed with plastic, it has the same physical and mechanical properties as hardwood pressure, bending, and so on, and its durability is significantly better than ordinary wood materials. Surface hardness is high, generally 2-5 times that of wood.

1. Products with the same processing properties as logs, can be nailed, drillable, cuttable, bonded, secured with nails or bolts, smooth and delicate surface, no sand and paint, its paint adhesion is good, but also according to personal preferences paint.

2. Products have better physical properties than logs, better than wood size stability, will not produce cracks, warping, no wood scars, twill, add colorants, coatings or composite surface can be made into colorful products, so no timed maintenance.

3. Be able to provide a variety of specifications, sizes, shapes, thickness needs, but also to provide a variety of design, colors,s and wood-printed finished products, to give customers more choice.

4. Products with fire, waterproof, corrosion, moisture resistance, not insect decay, not long fungi, acid and alkali, non-toxic, non-polluting, and other excellent performance, low maintenance costs.

5. Product use has a similar wooden appearance, higher hardness than plastic, long life, thermoplastic molding, high strength, energy saving.

6. the Product quality, lightweight, insulation, smooth and flat surface, no formaldehyde and other harmful substances, non-toxic, non-polluting.

Product process and classification

Wood-plastic can be used in a variety of places indoors and outdoors. The main materials of domestic wood-plastic are divided into PE wood plastic and PVC wood plastic two categories. PVC wood-plastic is also known as eco-wood.

PE wood plastic advantages: excellent waterproof and anti-corrosion, high hardness, heat-prone buckling, but the use of thickening or porous hollow structure effect is good.

Pe wood molding disadvantages:1. . The life of the outdoor application of the product is limited; Antioxidant and anti-light decomposition ability is poor, even if the addition of anti-oxygen agents and UV reference agents, the effect is not ideal, but also affect product strength and colorfastness; Product appearance color pure one, no woody sense, the appearance of poor results.

PVC wood-plastic advantages:1.PVC wood-plastic products can be made of new materials, can also be made of old materials (and PE with new materials is too expensive, products have no way to enter the market), modification is also easier, supplementary quantity depends on the quality of production;2. PVC can be made into low foaming wood-plastic products, so lower cost, think suitable for the use of co-extruded form (double material multi-material co-squeezing or steel plastic co-squeezing), strength and wood texture is good;3.PVC can be secondary processing A variety of exterior embellishments or paints cover UVs Paint, the product is good-looking and colorfastness; PVC wood-plastic products are also excellent waterproof and corrosion-resistant.

Pe wood plastic and PVC wood plastic difference:

1. The method is different: PE wood plastic product preparation mainly adopts the cold push method, PVC wood plastic product preparation can be divided into vacuum molding, cold push method, and three-roll suppression.

2. Different raw materials: PE wood-plastic materials are mainly second-and third-level PE recycled materials added wood powder, calcium powder, and a small number of modifiers. The materials used to manufacture PVC wood molding are mainly PVC resin powder, PVC recycled material, wood powder, stone powder, and partial modifiers, etc.

3. Performance is different: PE wood-plastic products are heavy, high hardness, brittle, creep is also large. PVC wood-plastic products are lightweight, poor hardness, good toughness, creep, no PE wood plastic products large.

4. Different uses: PE wood-plastic products are mainly outdoor garden construction, greenwood such as guardrails, floors, garbage cans, flower ponds, pallets, and so on. PVC wood-plastic products are mainly indoor decoration materials, such as doors, floors, kick lines, door covers, and so on.

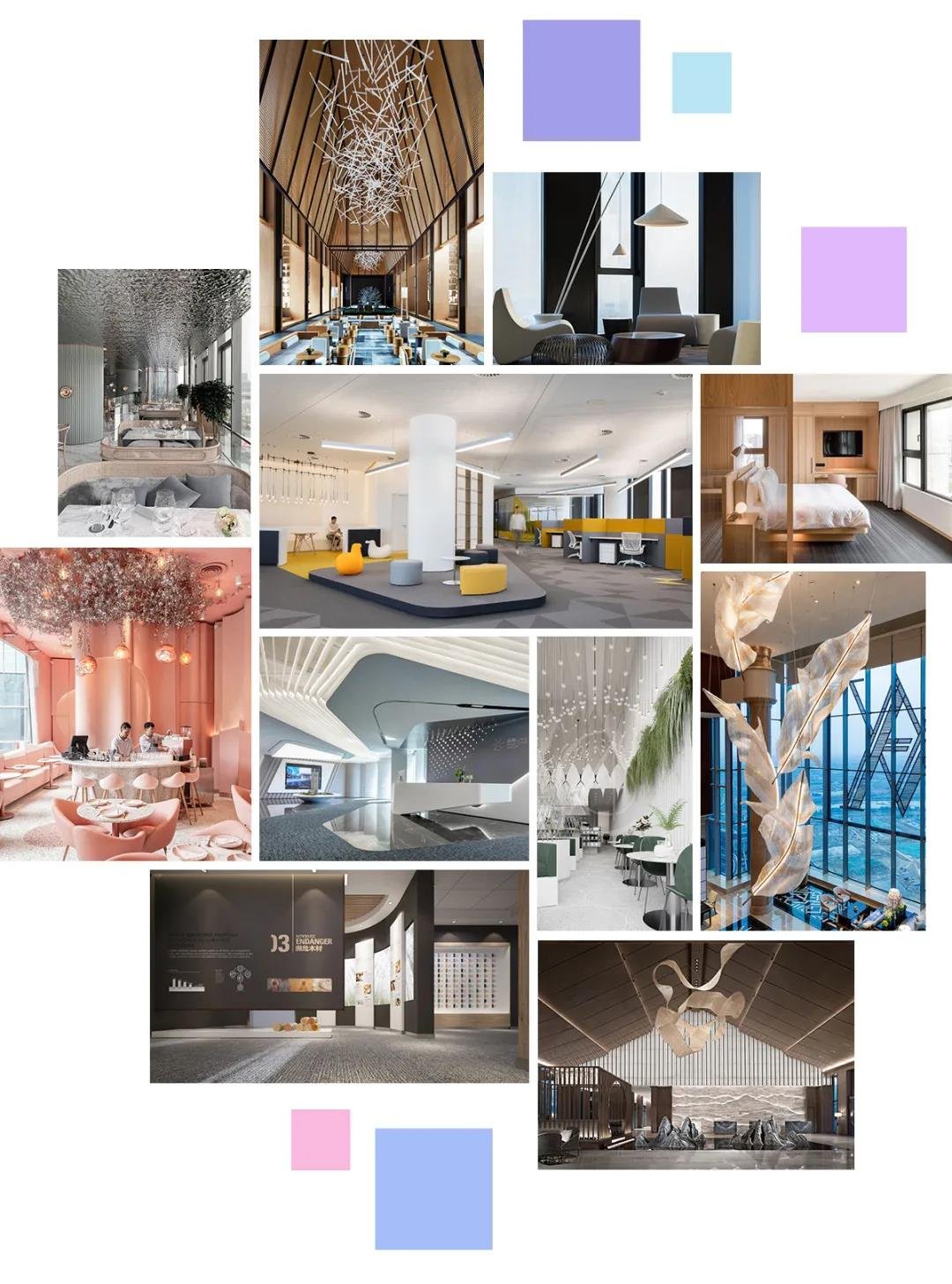

Plastic wood can be used for laying outdoor floors, as well as for curtain wall finishes on the exterior walls of buildings, and for the use of ceilings. All use keel hanging way, installation is convenient and simple.

The price range

80-300 yuan / square meters (materials).

Wood-plastic board domestic manufacturers more, the demand is also larger. Depending on the brand and quality, the price of some products is around 80-300 yuan per square meter, depending on the brand and quality.

The above price is only the market ordinary mid-range price, material prices according to its different projects, different brands, as well as customization and other reasons will have a larger fluctuation, for reference only.