Plain plate glass

Heat with red heat until softened

The calendering process is adopted to produce multiple pieces

Middle film or metal, silk

Pressed into semi-liquid glass strip

A special kind of glass

Wired glass has

Rich expressiveness

Varieties are

Embossed wire, polished wire, and colored wire glass, etc.

Shape has

Flat clamp wire, wave clamp wire, and groove clamp wire, etc.

Can be customized according to the pattern

Can be made in different colors

Common specifications

Common thickness is 6-16mm

And the thickness is not including the thickness of the middle filament

Therefore, the size must be determined in advance when designing and purchasing

The size is generally not less than 600mm×400mm

Not more than 2000mm×1200mm

Production Process

Rolling method

After the rolled metal wire mesh is unrolled by the mesh supply device

Sent to molten glass

After the glass liquid passes through the upper and lower calendar rolls

Wired glass

Therefore, it is more impact resistant than flat glass

And it will only form radial cracks when impacted

Without breaking into slag

Material characteristics

- Decorative

Wired glass can do many patterns

Also supports pattern customization

- Security

The impact strength is 5~10 times that of ordinary glass

When laminated glass encounters violent impact from external pressure

Radial cracks

Will not break into slag

3.Fire resistance

The temperature difference that can withstand is 3 times that of ordinary glass

Can withstand temperature changes of 300℃

Although the glass with wire mesh burst in the fire,

But wires or nets can also hold the debris

Can maintain integrity to a considerable extent

Prevent the flow of air and prevent the spread of smoke

Has good resistance to the spread of fire

Uses & Application Cases

Good properties of laminated glass

In the beginning, it was used more on doors and windows that are susceptible to vibration

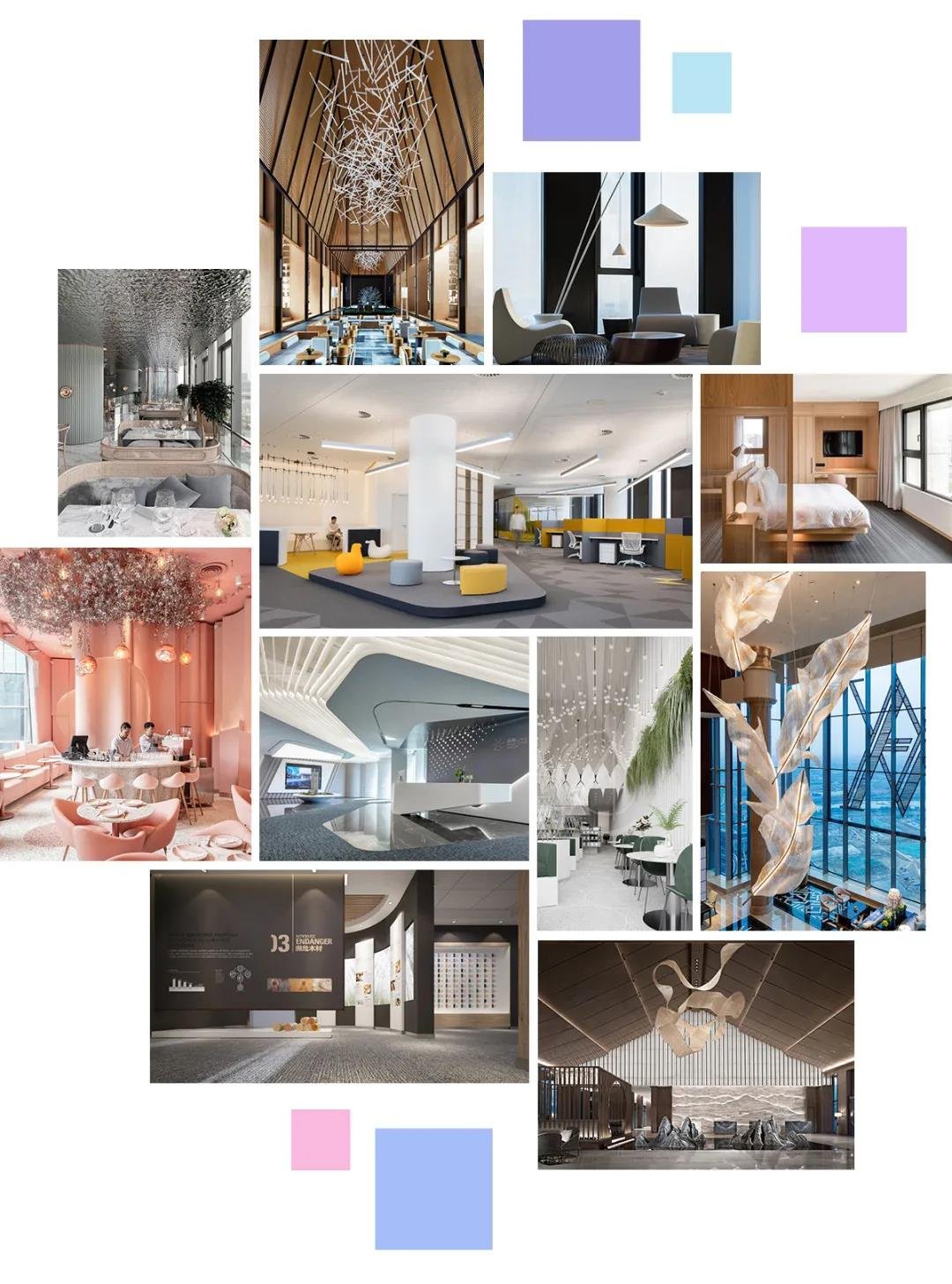

But in recent years it has been active indoors

Partition decoration application

Good-looking, not afraid of being hit, not afraid of breaking and hurting people

Construction installation & matters needing attention

Installation process

Glass selection and cutting

↓

Sub-specification stacking

↓

Wipe before installation

↓

Scrape bottom putty

↓

Mosaic glass

↓

Scrape putty, clean edges

Precautions

- Transportation:

During transportation, the glass should not be laid flat or slanted, and the length direction should be the same as the transportation direction of the vehicle and pay attention to rain and moisture.

After being transported to the construction site, it needs to be erected on the A-shaped shelf and stored in a dry room if it is not used temporarily.

- Rust prevention:

The wire mesh surface of the wire glass is specially treated, and it is generally not easy to rust. But the cut part is in an untreated state, so it will rust sometimes when it meets water.

Pay attention not only to transportation, but also to pay attention to the installation part to be easy to quickly drain rainwater when designing.

- During installation: use four-sided frame mounting. The glass and frame should be filled with high-quality sealing materials. It is recommended to use silicone rubber or polysulfide rubber sealing materials.

- Pay attention to the seams: When installing large-area patterned laminated glass, you should carefully cut them according to the design patterns, and the seams must be consistent to avoid misalignment, loosening and oblique bending.

To learn more about glass-related products, please enter the product page and article page